The carob tree

The carob tree, Ceratonia siliqua L., is a medium sized leguminous, evergreen tree with a well developed round crown and a short trunk. The tree is native widespread in the Mediterranean countries. Carob trees grow in their habitat usually in association with wild olives or pistachios, but carob plantations are also found. The trees grow best in calcareous soils, preferably near to the sea; they are drought resistant but tolerate only slight frost.

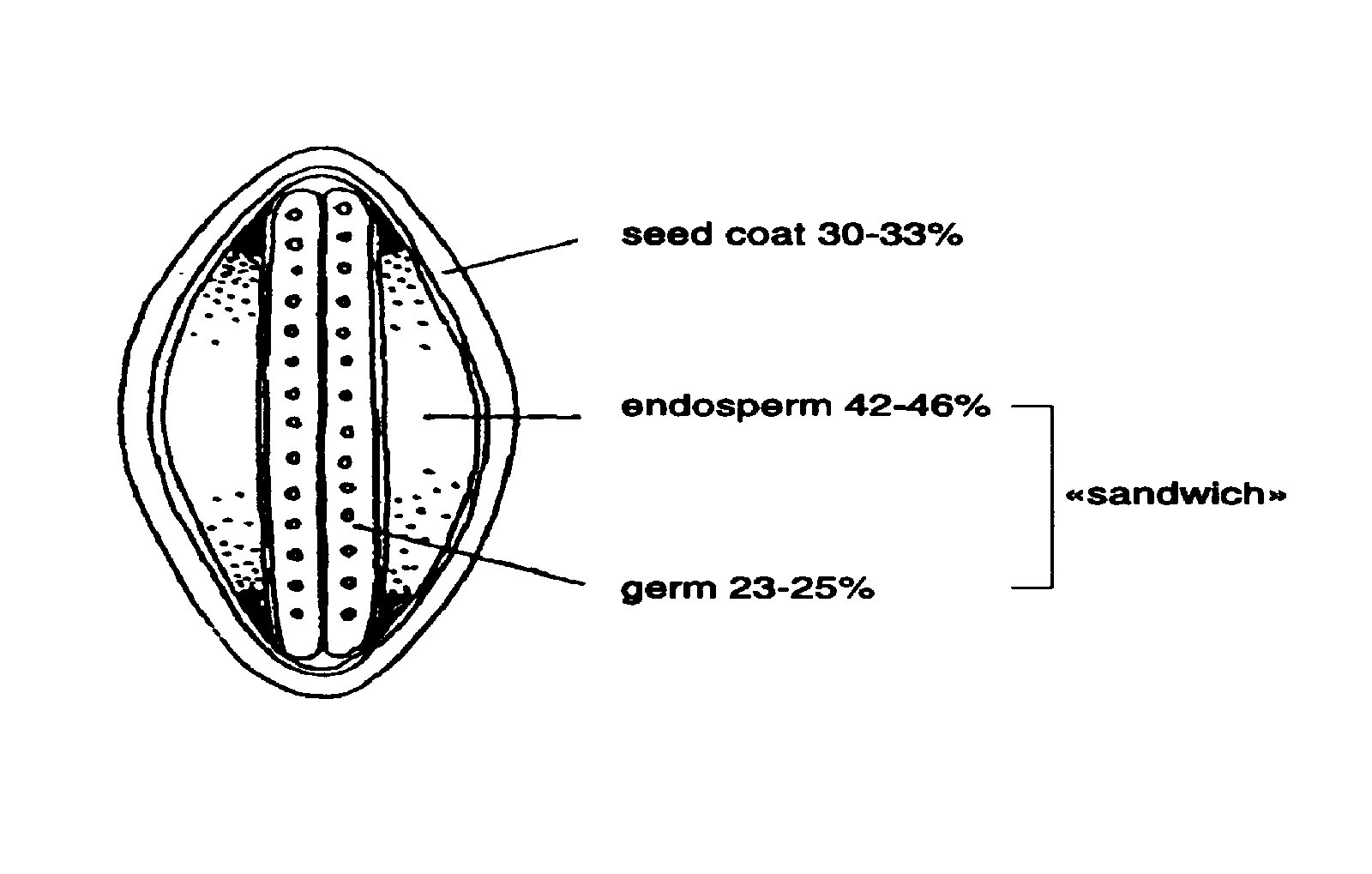

The quantity of carob bean kernels per pod depends on the variety and amounts to 8-15%.